People > Hyungkook Jeon - Micro/Nanofluidic BioMEMS Group

Hyungkook Jeon, PhD

Senior Postdoctoral Associate

Research Laboratory of Electronics

Google scholar

https://scholar.google.com/citations?user=K60hJAoAAAAJ&hl=ko

Hyungkook Jeon received his B.S. and Ph.D. degree in Department of Mechanical Engineering at Pohang University of Science and Technology (POSTECH), Korea, in 2010 and 2016, respectively. Before joining MIT in April 2018, he worked as a research assistant professor at POSTECH in South Korea.

Please see below for his research summary:

My previous and ongoing researches mainly focused on the development of biomedical devices for sample preparation, biochemical analysis, diagnostics, and biomanufacturing. In particular, i) particle manipulation using microfluidic methods and ii) wearable electronics based on micro/nano-fabrication methods are the key technologies that I have utilized and advanced for my researches. More details are described below:

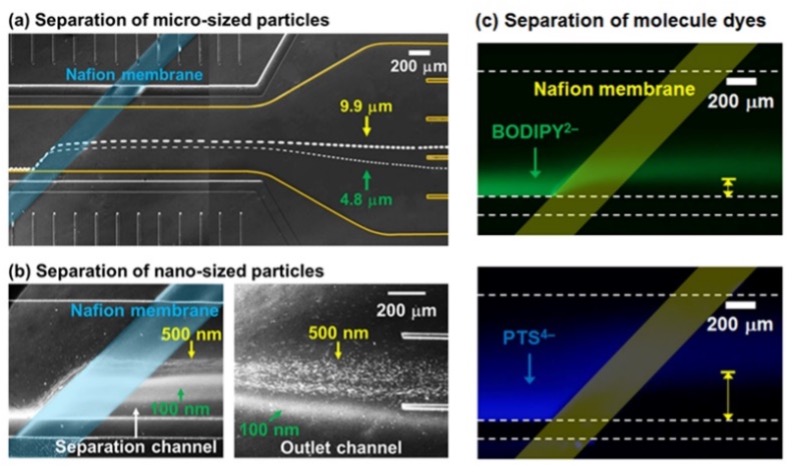

Ion concentration polarization-based micro/nano-particle separator

Figure 1.Micro- and Nano-size particle separation by ICP.

Ion concentration polarization (ICP) is a fundamental transport phenomenon in which ion-depletion and ion-enrichment regions are generated under an external field applied across an ion perm-selective membrane due to the ion flux mismatch. I developed a novel separation method, which was the first report using ICP to separate particles continuously (Figure 1). In the work, I analyzed the electrical forces in the ion-depletion region and successfully demonstrated the separation of micro- and nano-sized particles depending on their electrophoretic mobilities (Figure 1) [1,2].

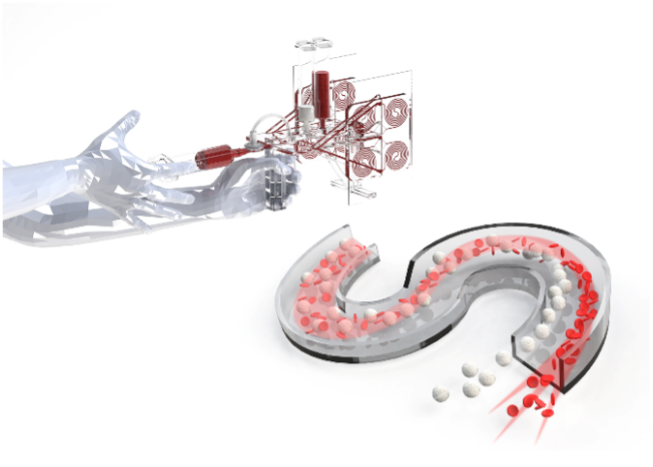

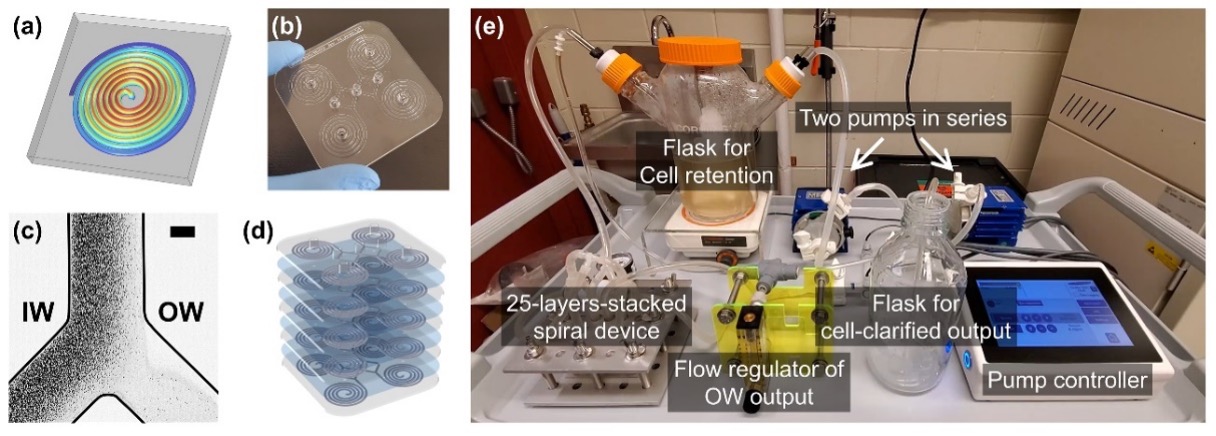

Multi-dimensional double spiral device and fully-automated recirculation platform

Figure 2. Schematics of the MDDS platform.

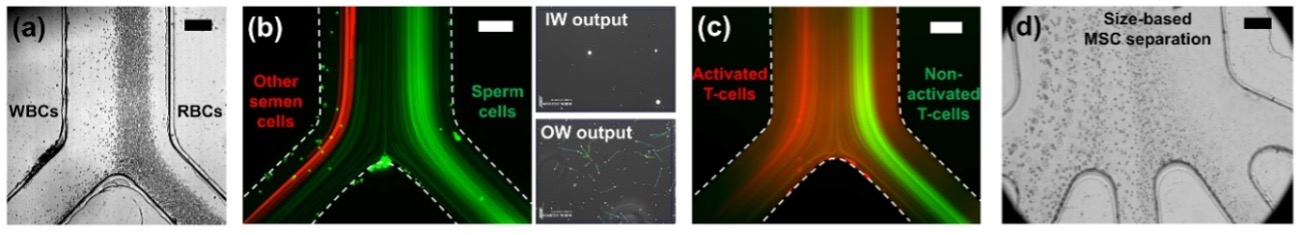

I developed a new type of inertial spiral microfluidic device, multi-dimensional double spiral (MDDS) device, which enables sample focusing and separation in a single device without sheath flow, resulting in high separation resolution and efficiency (Figure 2) [3]. Also, to obtain more purified and concentrated target particles, I also developed a new recirculation platform based on a check-valve which allows only one-way flow. In the platform, by the programmed back-and-forth syringe pump motions (or even hand-powered operation), the once-treated output can be processed again and again, resulting in higher purity and concentration. By combining the great features of the MDDS device and the recirculation platform, various sample preparations have been demonstrated such as 1) leukocyte separation for blood monitoring and sepsis diagnosis, 2) semen preparation for isolation of healthy sperm cells for Assisted reproductive technologies (ARTs) [4], 3) isolation of activated T-cells for better CAR-T cell manufacturing, and 4) Mesenchymal stem cells (MSC) separation for better tissue restoration (Figure 3).

Figure 3. Various sample preparation: (a) Blood separation, (b) Semen preparation, (c) Isolation of activated T-cells, and (d) Size-based MSC separation. All the scale bars represent 200 µm.

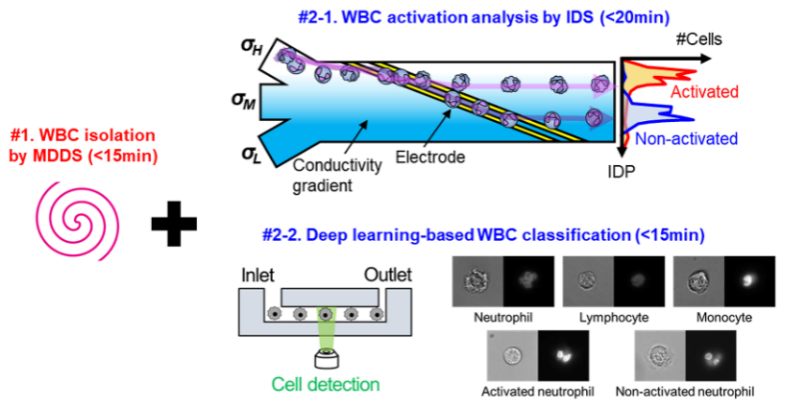

Integration of microfluidic sub-platforms

Figure 4. Schematics of the integrated platforms.

I developed fully-automated, sample-to-answer leukocyte activation analysis platforms for monitoring immune responses in sepsis and counting sub-populations of leukocytes, by integrating the MDDS platform with other downstream analysis platforms, including isodielectric separation (IDS) platform and machine-learning-based WBC classification platform (Figure 4) [5,6]. In the integrated platforms, the separated leukocytes from the MDDS platform can be automatically transferred to the downstream platforms and analyzed.

Development of deformation-free and mass-producible plastic devices

To move forward from the proof-of-concept device in a laboratory to the product to be used for real applications, I developed deformation-free and mass-producible plastic spiral microfluidic devices for disposable and high-throughput applications [7]. Based on numerical analysis of channel deformation, a PDMS spiral device was translated to its plastic version (Figure 5a,b). Moreover, using the multiplexed device made by stacking the plastic devices, we successfully demonstrated cell clarification with an industry-level throughput, which can be used for efficient production of therapeutic proteins such as antibodies or vaccines for COVID-19 (Figure 5c−e).

Figure 5. (a) Numerical analysis of channel deformation, (b) A picture of the plastic spiral device. (c) Trajectories of CHO cells at the outlet region. (d) A schematic of the multiplexed spiral device. (e) A picture of the ultra-high-throughput cell clarification platform using the multiplexed spiral device (at a processing rate of ~1 L/min).

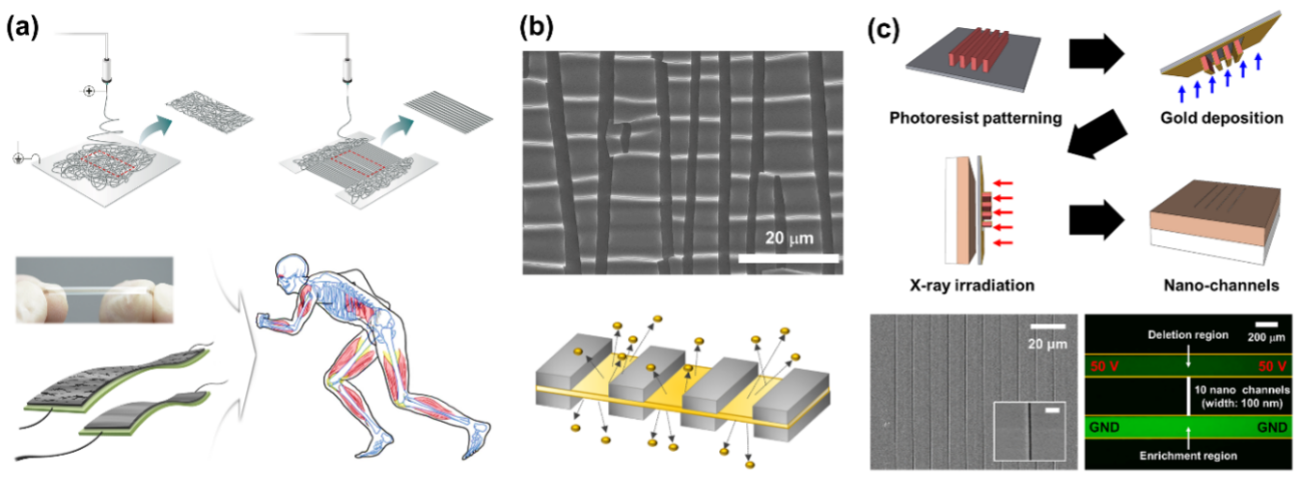

Micro/nano-fabrication techniques

I have many kinds of micro/nano-fabrication techniques, which include electrospinning, thin-metal-film deposition, controllable cracking structure, and X-ray irradiation lithography (Figure 6), and they have been used to fabricate (a) a stretchable strain sensor for motion monitoring [8–10], (b) a controllable drug delivery system [11], and (c) long nanochannels for nanofluidic applications [12]. I expect the novel micro/nano-fabrication techniques I have developed can be used to develop advanced biomedical devices in the future.

Figure 6. Micro/nano-fabrication techniques: (a) Stretchable strain sensor for motion monitoring based on controllable nanocracking structure in electrospun micro-fibers and a thin metal film, (b) Cracking-structure-based controllable drug delivery system, (c) Nanochannel fabrication by X-ray lithography for nanofluidic applications.

Selected publications

[1] H. Jeon, H. Lee, K. H. Kang, and G. Lim, Ion Concentration Polarization-Based Continuous Separation Device Using Electrical Repulsion in the Depletion Region., Sci. Rep. 3, 03483 (2013).

[2] H. Jeon, Y. Kim, and G. Lim, Continuous Particle Separation Using Pressure-Driven Flow-Induced Miniaturizing Free-Flow Electrophoresis (PDF-Induced μ-FFE), Sci. Rep. 6, 19911 (2016).

[3] H. Jeon, B. Jundi, K. Choi, H. Ryu, B. D. Levy, G. Lim, and J. Han, Fully-Automated and Field-Deployable Blood Leukocyte Separation Platform Using Multi-Dimensional Double Spiral (MDDS) Inertial Microfluidics, Lab Chip 20, 3612 (2020).

[4] H. Jeon, C. Cremers, D. Le, J. Abell, and J. Han, Multi-Dimensional-Double-Spiral (MDDS) Inertial Microfluidic Platform for Sperm Isolation Directly from the Raw Semen Sample, Sci. Rep. 12, 4212 (2022).

[5] H. Jeon, D. Lee, B. Jundi, M. Pinilla-Vera, R. M. Baron, B. D. Levy, J. Voldman, and J. Han, Fully Automated, Sample-to-Answer Leukocyte Functional Assessment Platform for Continuous Sepsis Monitoring via Microliters of Blood, ACS Sensors 6, 2747 (2021).

[6] H. Jeon, M. Wei, X. Huang, J. Yao, W. Han, R. Wang, X. Xu, J. Chen, L. Sun, and J. Han, Rapid and Label-Free Classification of Blood Leukocytes for Immune State Monitoring, Anal. Chem. acs. analchem.2c00906 (2022).

[7] H. Jeon, T. Kwon, J. Yoon, and J. Han, Engineering a Deformation-Free Plastic Spiral Inertial Microfluidic System for CHO Cell Clarification in Biomanufacturing, Lab Chip 22, 272 (2022).

[8] H. Jeon, S. K. Hong, M. S. Kim, S. J. Cho, and G. Lim, Omni-Purpose Stretchable Strain Sensor Based on a Highly Dense Nanocracking Structure for Whole-Body Motion Monitoring, ACS Appl. Mater. Interfaces 9, 41712 (2017).

[9] H. Jeon, S. K. Hong, S. J. Cho, and G. Lim, Fabrication of a Highly Sensitive Stretchable Strain Sensor Utilizing a Microfibrous Membrane and a Cracking Structure on Conducting Polymer, Macromol. Mater. Eng. 303, 1 (2018).

[10] S. Hong, S. Yang, S. Cho, H. Jeon, and G. Lim, Development of a Waterproof Crack-Based Stretchable Strain Sensor Based on PDMS Shielding, Sensors 18, 1171 (2018).

[11] H. Jeon, M. S. Kim, S. K. Hong, S. J. Cho, and G. Lim, Tensile Strain-Controlled Drug Delivery System Based on a Cracked Metal Structure, Sensors Actuators B Chem. 270, 64 (2018).

[12] H. Jeon, J. H. Kim, and G. Lim, A Novel Nanochannel Fabrication for Nanofluidic Applications Using Synchrotron Radiation via a Micro Patterned X-Ray Mask, RSC Adv. 6, 46068 (2016).