Hyun S. Kum, Hyungwoo Lee, Sungkyu Kim, Shane Lindemann, Wei Kong, Kuan Qiao, Peng Chen, Julian Irwin, June Hyuk Lee, Saien Xie, Shruti Subramanian, Jaewoo Shim, Sang-Hoon Bae, Chanyeol Choi, Luigi Ranno, Seungju Seo, Sangho Lee, Jackson Bauer, Huashan Li, Kyusang Lee, Joshua A. Robinson, Caroline A. Ross, Darrell G. Schlom, Mark S. Rzchowski, Chang-Beom Eom & Jeehwan Kim

DOI: 10.1038/s41586-020‑1939‑z

Abstract:

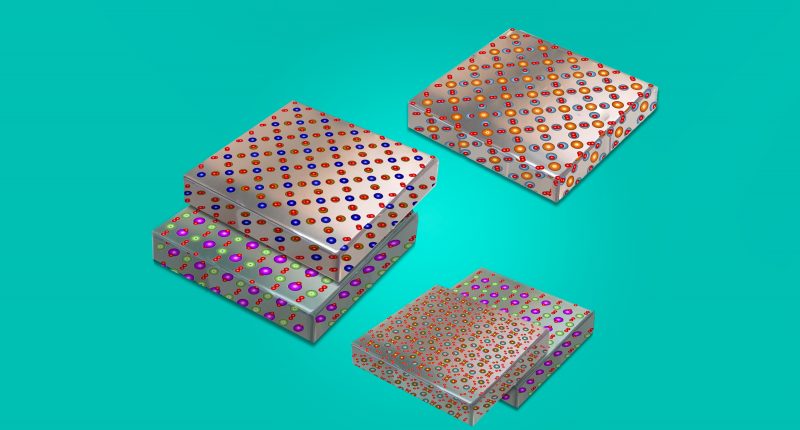

Complex-oxide materials exhibit a vast range of functional properties desirable for next-generation electronic, spintronic, magnetoelectric, neuromorphic, and energy conversion storage devices1,2,3,4. Their physical functionalities can be coupled by stacking layers of such materials to create heterostructures and can be further boosted by applying strain5,6,7. The predominant method for heterogeneous integration and application of strain has been through heteroepitaxy, which drastically limits the possible material combinations and the ability to integrate complex oxides with mature semiconductor technologies. Moreover, key physical properties of complex-oxide thin films, such as piezoelectricity and magnetostriction, are severely reduced by the substrate clamping effect. Here we demonstrate a universal mechanical exfoliation method of producing freestanding single-crystalline membranes made from a wide range of complex-oxide materials including perovskite, spinel and garnet crystal structures with varying crystallographic orientations. In addition, we create artificial heterostructures and hybridize their physical properties by directly stacking such freestanding membranes with different crystal structures and orientations, which is not possible using conventional methods. Our results establish a platform for stacking and coupling three-dimensional structures, akin to two-dimensional material-based heterostructures, for enhancing device functionalities8,9.