The T.J. Rodgers RLE Laboratory is a 2500 square foot space in the heart of MIT’s Research Laboratory of Electronics (RLE). The T.J. Rodgers RLE Laboratory supports research prototyping needs across the broad mission of RLE, providing a well-equipped, modern electronics laboratory along with hand and machine tools suitable for assembling, testing, and packaging prototypes. The electronics laboratory includes oscilloscopes, network analyzers, spectrum analyzers, power supplies, LCR/impedance meters, and other state-of-the-art test equipment. The lab also contains computing equipment and CAD software tools that support prototyping and design. It contains optical microscopy facilities, 3D printing, high-power utility connections, and has access to shared prototyping facilities across the MIT campus and beyond.

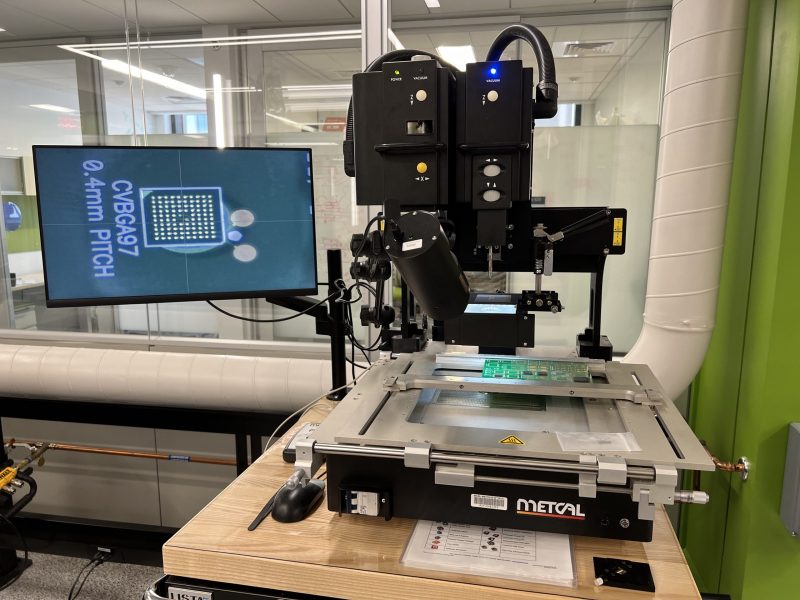

Examples of specific laboratory equipment and capabilities – not exhaustive – are provided below: The lab’s LPKF Protolaser U4 provides general purpose micro-machining as well as rapid prototyping of high-density multilayer PCBs by laser structuring copper, aluminum, steel and other materials, as well as laser drilling and cutting of PCB, electrode and stencil materials including FR4, various high-frequency laminates, ceramics, solder mask, plastics and steel. The lab provides a plating apparatus to make copper through-hole vias and gold-plated surfaces for wire bonding, better conductivity, and corrosion resistance. Printed circuit board assembly tools include two Metcal CV-5200 dual output soldering stations, UltraFine and Advanced handpieces, a Pace PRC-2000 rework station that includes a programmable solder paste-dispense pump, a Metcal Scorpion pick-and-place rework station, and a solder reflow oven. The lab provides a broad set of test and measurement equipment including multiple Keysight DSOX4145A oscilloscopes featuring 1.5 GHz analog bandwidth and dual built-in signal generators; programmable DC power supplies including a Keysight N6781A source measurement unit for dynamic current drain, battery drain, and ultra-low IC test; as well as a vector network analyzer. The lab’s Stratasys J5 Medijet, a polyjet 3D printer, can print up to five materials simultaneously at 18 um layer thickness, 50 um resolution within each layer and ±150 um dimensional accuracy on the finished part. This multi-material capability enables 3D printed parts comprising rigid or elastic materials. The materials can be full-thickness deep black, white or optically clear with full-color finishes. Available materials include biocompatible clear or opaque materials, evaluated under EN ISO 10993 for cytotoxicity, genotoxicity irritation and other standards. The resulting fixtures, jigs or educational models have reliable strength, stiffness and machinability. Lab computing facilities include a high-power Dell Precision 5820 workstation with an Nvidia RTX A4500 GPU for SolidWorks, AutoDesk Suite, Adobe Creative Cloud, SPICE, KiCAD and other simulation software. The lab also provides passive and active components, MCU and FPGA evaluation boards, data acquisition units, inspection scopes, hand and power tools, fasteners and other items needed to complete research apparatus and prototypes.

The lab is directed by a veteran engineer and manager with a 25-year career in industry and academia with experience including micro- and nano-technology design and fabrication, electronics, signals and systems, optics, advanced microscopy, materials science, micro-fluidics, electrophysiology and stem cell biology. The lab manager mentors graduate students and advises on engineering designs. The director also provides technical input and oversees the growth of the lab by adding capabilities responding to ever-changing needs in RLE.

For more information please visit the T.J.Rodgers RLE Laboratory Website